Mist eliminators generally consist of two types – diffusion and impaction style designs. Impaction mist eliminators can be vertical fiber bed elements, a have a metal mesh pad horizontal design or have a chevron-staggered plate construction. Elessent Clean Technologies offers Brink® diffusion and impaction fiber beds and MECS® TowerGARD® mesh pad mist elimination products. Since fiber bed mist eliminators are the most versatile and can be designed to remove any liquid or any soluble solid mist from any gas stream, this article focuses on high-efficiency fiber bed mist eliminators.

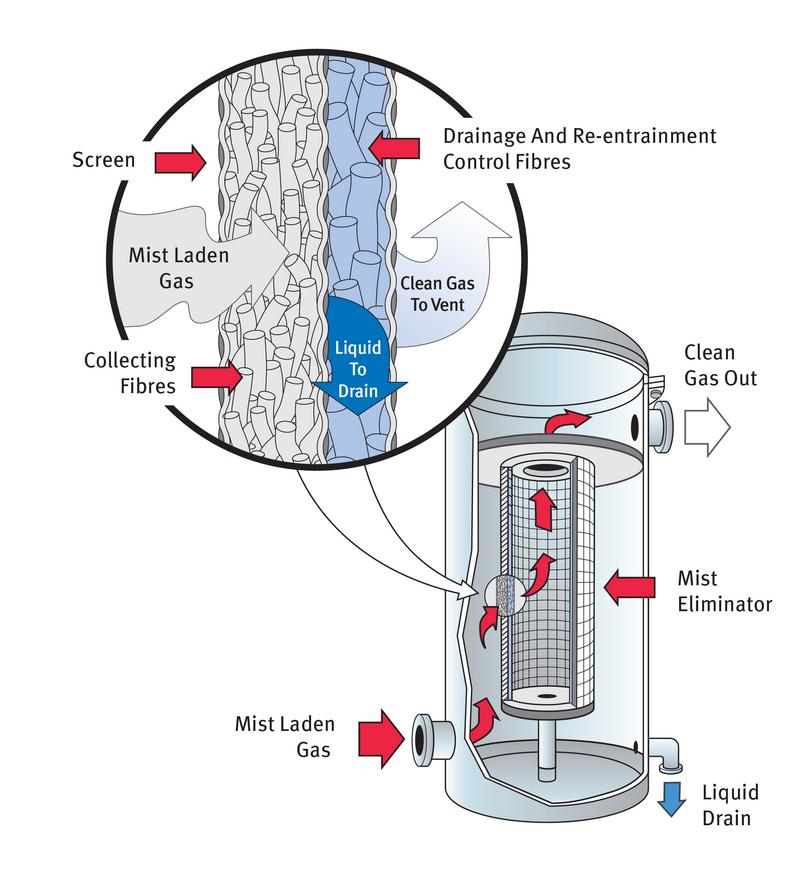

Fiber bed mist eliminators consist of thick layers of very fine fibers placed between two concentric cylindrical screens or cages. Chemically resistant glass fibers, synthetic fibers and other special types of fibers are used as the fiber bed material, depending on the process environment. Structural screen/cage parts and flanges are made of any weldable metal, plastic or glass reinforced resins.

All fiber bed mist eliminators operate in a similar manner. Gases containing mist particles are directed horizontally through the fiber bed, and the mist particles collect on the individual fibers within the fiber bed and coalesce to form liquid films. These liquid films are then moved through the fiber bed by the gas flow, and the liquid drains off the downstream face of the fiber bed by gravity. Fiber bed mist eliminators are typically installed in a vessel or tank and the collected liquid is continuously drained from within the tank.

A fiber bed design innovation is the addition of a second coarser fiber layer on the downstream side. This additional layer expedites drainage and prevents re-entrainment of the liquid back into the gas stream.

Mist is the term used to describe a phenomenon of small, finely divided liquid aerosol droplets suspended or dispersed in air or process gases. Mists are most commonly formed when warm, saturated gas meets sudden cooling, such as in a heat exchanger or when saturated hot and cold gases are mixed. The term mist usually refers to liquid particles under 10 microns in diameter. Particles over 10 microns are often called sprays, and very small mist particles under 1 micron in diameter are called submicron mist particles. A good rule of thumb to identify small submicron mists is that they are often visible as a cloud or haze. Common examples include smog, clouds, blue asphalt “smoke” from tar pots and white clouds of condensed water vapor from power plant smokestacks.

Mist can be formed in chemical and other manufacturing processes by three distinct and different methods:

Particles larger than three microns are collected when their momentum prevents them from following gas streamlines around fibers. They leave the streamline, strike a fiber and are collected by the fiber.

Extremely fine particles have random side-to-side movement caused by collisions with gas molecules. A 0.1 micron particle will have about ten times the Brownian movement or random motion of a 1.0 micron particle, greatly increasing the probability of collision with a fiber.

After collection, the mist droplets coalesce on the individual fibers in the fiber bed and begin to drain.

Elessent Clean Technologies welcomes the opportunity to investigate and recommend solutions to any mist-related air pollution or in-process gas handling problem that you may have. Learn more about MECS® Brink® Mist Eliminator Services for trouble-free installation and operation, including fiber sampling, mist sampling, repacks and repairs.