The MECS® DynaWave® reverse jet scrubber technology is the only wet scrubbing technology that accomplishes multiple functions in one vessel and can use a variety of reagents to guarantee low emissions for a wide range of industries. Its unique flexibility is due to specific technical features that provide exceptionally high on-stream reliability and outstanding operational comfort while at the same time making it possible to optimize CAPEX and OPEX expenditures.

Elessent Clean Technologies has more than 40 years of emission control expertise and over 500 successful wet gas scrubber references around the globe. More than 400 of these references were designed with the MECS® DynaWave® reverse jet scrubber technology. Its distinctive design and many benefits help to reduce air emissions and increase efficiency and cost-effectiveness in refineries, sulfur plants, sulfuric acid plants, metallurgical plants, power, cement kilns, waste incinerators and many other applications.

DynaWave® reverse jet scrubbing is our preeminent solution for reliable compliance with increasingly stringent air pollution control requirements. It combines acid gas absorption, particulate removal and hot gas quenching— all in one vessel. In many conventional scrubbers or simple caustic scrubbers, each function occurs in a different area of the vessel, or outside the scrubber altogether. With DynaWave® technology, even oxidation is achieved in situ in the same vessel sump. No other scrubber is capable of this performance. Our straightforward approach reduces both capital and operating costs. Most importantly, it allows for minimal equipment inside the vessel making the DynaWave® scrubber an extremely reliable and low-maintenance scrubber.

Our engineering experts can customize DynaWave® solutions for your specific application needs, as we’ve already done for many industries. Major companies in several high-demand industries currently depend on DynaWave® technology to meet their clean air requirements.

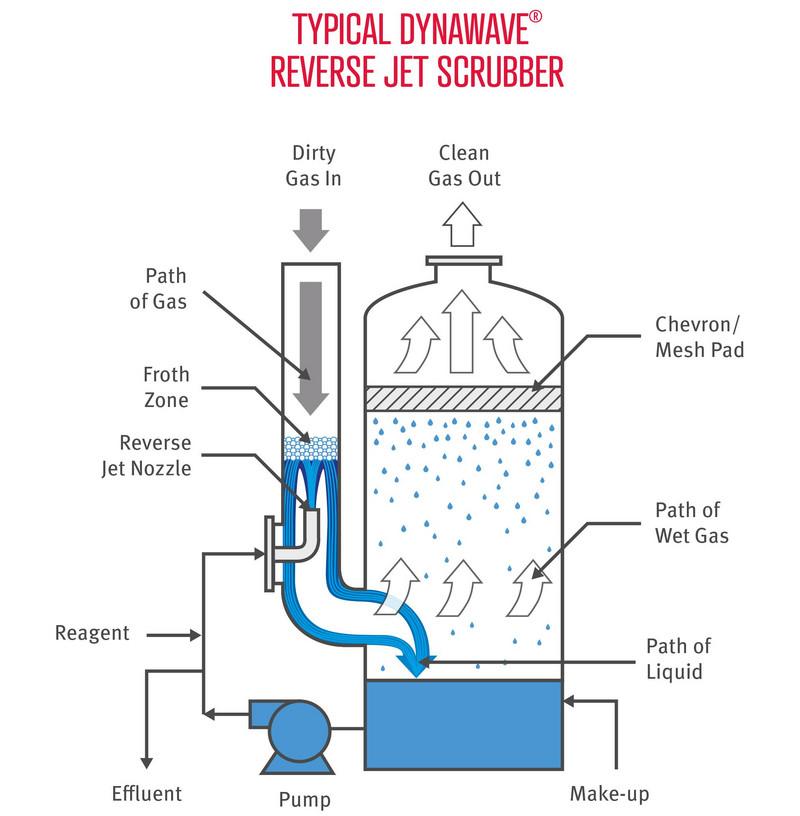

The key is the intimate mixing of the gas and scrubbing liquid in the inlet barrel. The DynaWave® reverse jet scrubber is an open duct in which scrubbing liquid is injected, through a non-restrictive reverse jet nozzle, counter current to the dirty inlet gas.

Gas enters at the top of the vessel and travels down the inlet barrel while the liquid is sprayed upward into the barrel. The liquid collides with the down-flowing gas to create the “Froth Zone,” a region of extreme turbulence with a high rate of mass transfer.

The clean, water-saturated gas continues through the scrubber vessel to mist removal devices. The liquid reverses direction and returns to the vessel sump for recycling back to the reverse jet nozzle.

DynaWave® technology has been used to clean small gas flows from a couple of cubic meters per minute to flows well above one million cubic meters per hour. It has treated gases up to 1200°C / 2200°F. It has removed dust, acid gases (such as SO2, HCl, HBr, HI, H2S, HCN) and ammonia with all kinds of different reagents (caustic, limestone in Australia & the USA, milk of lime, ZnO in Australia and Belgium, soda ash, etc.).