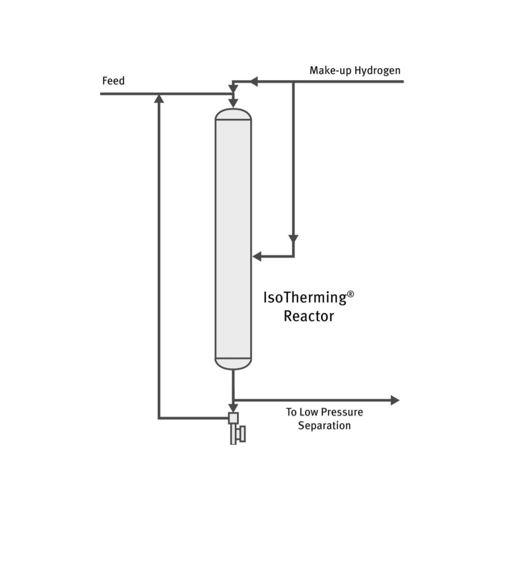

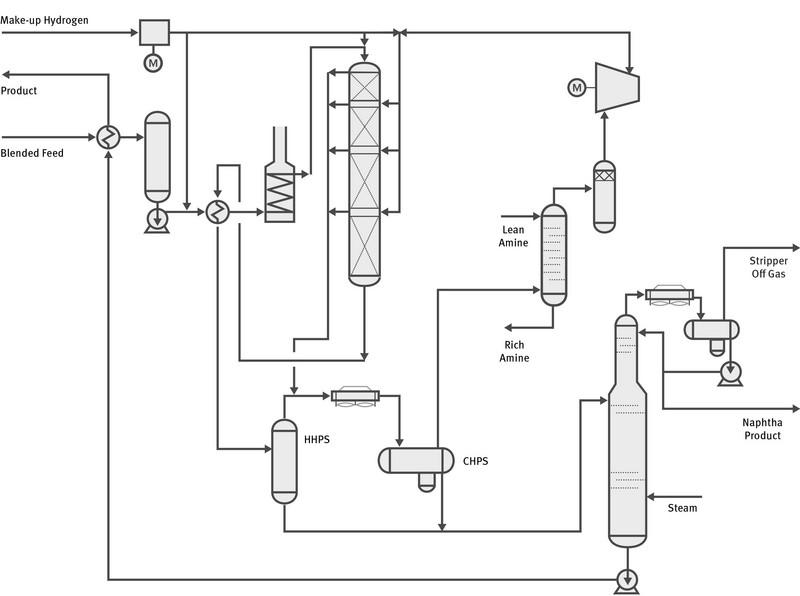

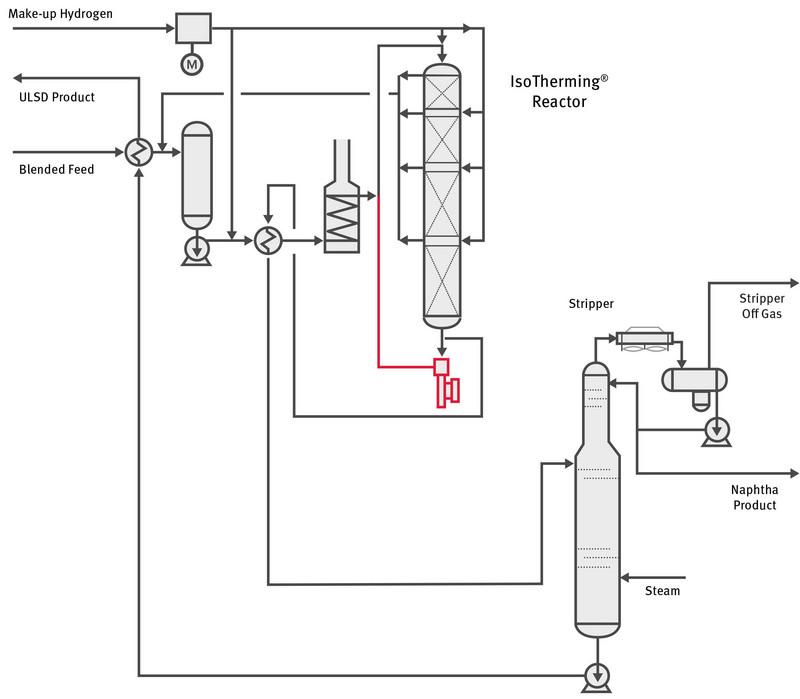

The fundamental principle of the IsoTherming® technology is the ability to provide the hydrogen necessary for the chemical reactions using a single-phase liquid-full reactor design rather than the historical trickle bed two-phase system. The reactor feed is saturated with hydrogen, which eliminates the need for a recycle gas compressor and amine absorber. To satisfy hydrogen requirements within the reactor, supplementary hydrogen can be added by means of an external liquid recycle stream or inter-bed hydrogen injection.

The IsoTherming® Hydroprocessing Technology is a commercially proven flexible process that provides refiners worldwide with a more economical means to produce today’s cleaner transportation fuels. Implementing the IsoTherming® technology enables refiners to produce high-quality, low-sulfur fuels compliant with local environmental regulations. Utilizing a liquid-full reactor design with the IsoTherming® technology, operating costs are significantly reduced when compared to the historical two-phase trickle bed hydroprocessing technology. In addition, the proven reliability and operational flexibility of the IsoTherming® technology enables refiners to increase life cycle and prolong more beneficial yield and density shift.

The IsoTherming® technology is a safe and easy process to operate. Elimination of the recycle gas compressor, high pressure heat exchangers and vessels not only reduces the quantity of high pressure equipment from the system and therefore reduces plot space requirements, but also significantly reduces the hydrogen inventory in the hydroprocessing unit. The IsoTherming® technology is also commercially proven to recover quickly from process upsets without loss of catalyst activity.

There are multiple considerations taken into account when designing an IsoTherming® unit. The design of the IsoTherming® unit relies on feedstock characteristics and product specifications for sulfur, nitrogen, olefin content and poly-aromatics. These variables will dictate the number of catalyst beds, recycle ratio and amount of catalyst volume required to operate the liquid-full IsoTherming® reactor.

The IsoTherming® reactor design is robust and has been commercially proven to successfully process challenging feedstocks. This flexibility offers refiners the ability to process a wide variety of feeds to maximize refinery profits.

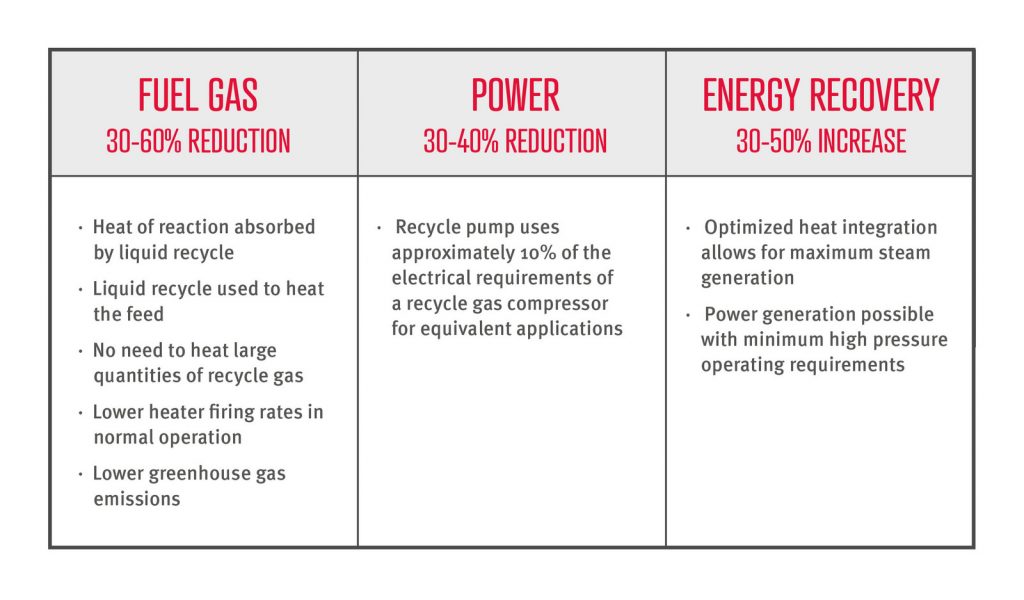

By eliminating the hydrogen gas compressor and its ancillary recycle loop equipment, significant maintenance and operating cost savings can be realized. In addition, for feed types with highly exothermic reactions, the IsoTherming® process recovers the heat of reaction by recycling a portion of the hot reactor effluent back to the inlet of the reactor. This direct transfer of heat to the feed in turn reduces the fired heater duty which results in not only an operating cost savings but also reduces the level of emissions from the unit. Furthermore, the IsoTherming® process does not require heating of large quantities of recycle gas in the charge heater, providing additional fuel gas consumption savings. Overall, the IsoTherming® technology has consistently demonstrated a 30-60% utility savings over trickle bed technology including:

The IsoTherming® technology has demonstrated significant capital cost advantages. These advantages are particularly pronounced in hydroprocessing revamps and low hydrogen consumption applications.

Capital cost savings over 30% have been achieved; however, these are dependent upon the application under consideration and global economic factors.

As mentioned, the IsoTherming® technology recovers the heat of reaction by recycling a portion of the hot hydrotreated product back to the inlet of the reactor. As such, the feed/effluent exchanger heat duty requirements are reduced, which contributes to a significant reduction in high pressure heat exchanger shells that are required when comparing to an equivalent trickle bed design. Furthermore, separation of hydrocarbon and gas in order to recover the recycle gas is not required with the IsoTherming® process.

Consequently, the IsoTherming® process does not necessitate high or low pressure separation vessels and air coolers for the reactor effluent before entering the stripper or fractionator. For projects with low hydrogen consumption, the ability to supply the hydrogen through feed saturation without requiring a recycle pump results in even fewer pieces of high pressure equipment, resulting in lower capital costs.

For example, one refinery with a commercially operating IsoTherming® Diesel Hydrotreating unit experienced a four-hour power failure event. Within five hours of power returning to the unit, the reactor returned to stable operation, producing on-spec product at the same reactor temperature.

The benefit of quick recovery time for the IsoTherming® technology is achieved for a variety reasons. First, the hydrogen content within the reactor is limited by solubility, reducing the number of hydroprocessing chemical reactions, (and associated heat release) that could occur. Secondly, the liquid in the reactor functions as a heat sink for the exothermic chemical reactions which limits undesired temperature rise and eliminates any potential for runaway in the IsoTherming® reactor.

This rapid return to original operating conditions without any long-term damage demonstrates the IsoTherming® technology’s robustness and inherently safe operation compared to trickle bed technology. In contrast, the unit downtime could be days in a similar power failure event in a trickle bed unit in addition to the potential of experiencing a reactor runaway or catalyst deactivation.